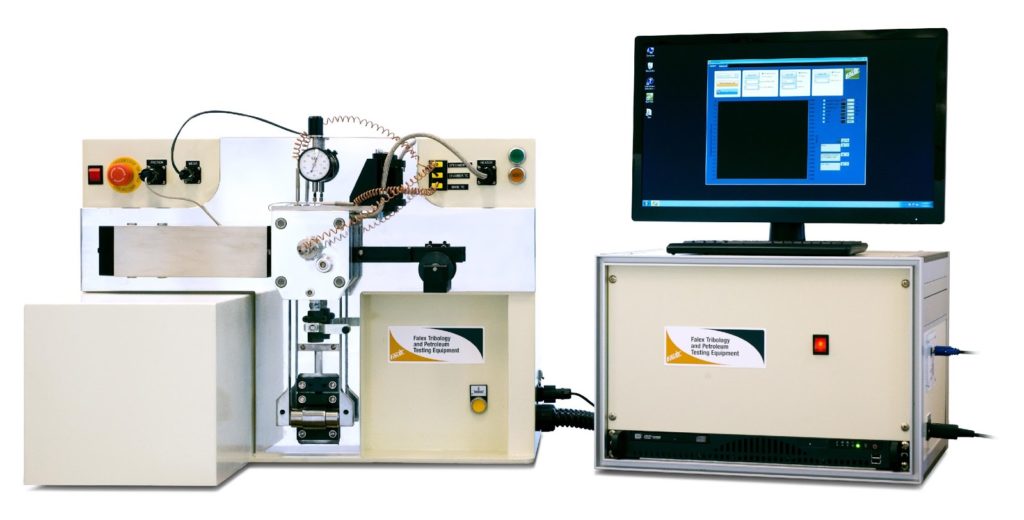

Four Ball

The new and improved Falex Four-Ball introduces a fresh approach to four-ball testing. This revolutionary concept yields an instrument that is smaller, safer, and more versatile with improved automation, calibration, and increased capabilities. The new Four-Ball meets the following standard test methods. ASTM D2266, ASTM D4172, ASTM D5183, ASTM D2596 ASTM D2783, IP 300, CEC […]

Multispecimen – MCTT

The Falex MCTT is a versatile system which is perfect for the evaluation of friction, wear and abrasion characteristics of materials, coatings and lubricants. This single apparatus accommodates an ever-increasing number of test geometries and conditions. The Multispecimen meets the following standard test methods. ASTM D3702, ASTM G99 Click here for further information

Pin on Vee Block

The Falex Pin on Vee is used to evaluate wear, friction, and extreme pressure properties of lubricants, coatings, and materials. Manual and automated systems provide easy operation, calibration, data acquisition, and test reports. Consumable test pieces are available from other materials to better match field conditions. The Pin On Vee meets the following standard test […]

Miller Machine

This test instrument is used to develop data to determine the relative abrasivity of slurries (Miller Number). It can also be used to evaluate the wear resistance of different materials using a standard abrasive slurry media (SAR Number). Originally used to evaluate slurry abrasion of materials passing through fluid handling pipelines. Today it is used […]

Fretting Wear

The revamped Fretting Wear Test Machine from Falex uses two ball thrust bearings, lubricated with the test grease and oscillated through an arc of 0.21 radians (12Åã) at a frequency of 30.0 Hz (1800 cpm) under a constant load of 2450 N (550 lbf ) for 22 hours at room temperature. Fretting wear is determined […]

Dry Sand/Rubber

The Dry Sand/Rubber Wheel Apparatus offers the most accurate testing of abrasion resistance on a variety of materials. Falex is listed as the sole source of supply in ASTM G65 and is the only commercially available apparatus that has participated in Inter-Laboratory Studies as support for the precision statements. The rugged and reliable instrument can […]

Block on Ring

The Falex Block-on-Ring test machine dependably evaluates the friction and wear characteristics of materials and various coatings and lubricants in a multitude of simulated test conditions. It gives the user control over the load, speed, and environment of the test, and allows remarkably efficient download of the data into Excel spreadsheets with the Falex 330 […]

Air Jet Erosion

The Air Jet Erosion Test System controls a repeated impact erosion approach involving a small nozzle delivering a stream of gas containing abrasive particles which impact the surface of a test specimen. The amount of weight loss per unit of time represents the erosion or wear rate, providing laboratory scale erosion measurements under a range […]

Timken Test Machine

The Falex Timken Extreme Pressure Test Rig evaluates fluid lubricants and greases containing extreme-pressure additives. Improvements made by Falex include controlled rate test load and mechanical grease feeder systems, a test fluid recirculation system with temperature control, and an automatic fluid flow interrupter. Optional accessories include a variable speed motor and reservoir cooling system to […]

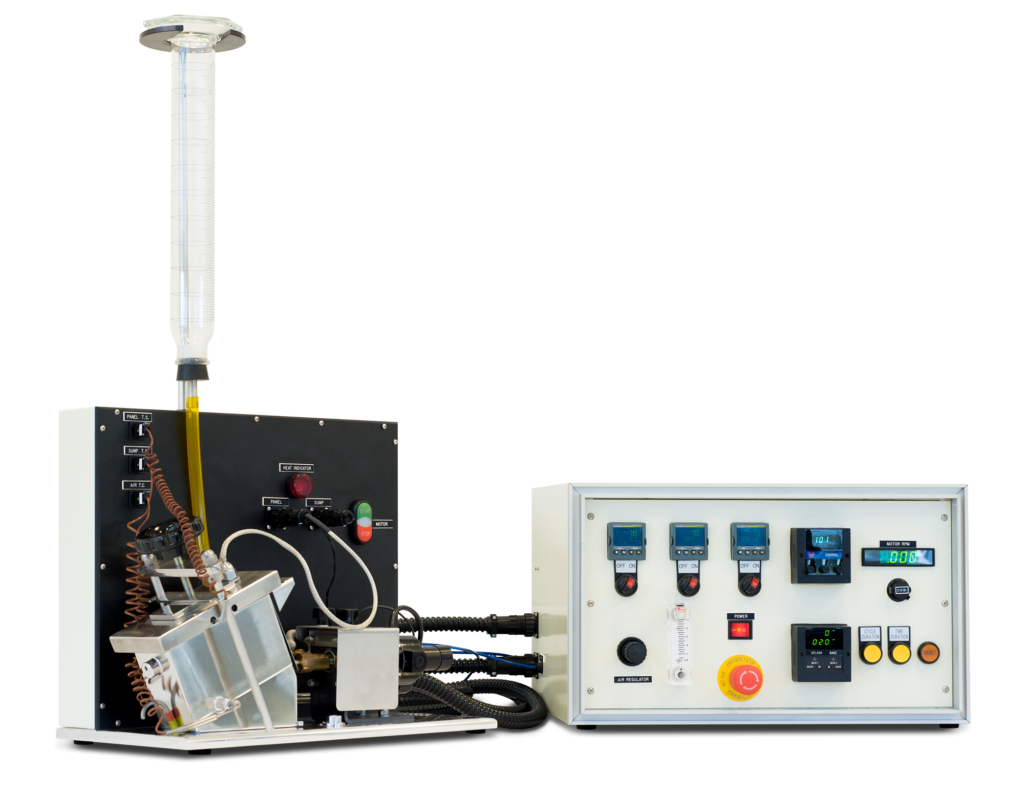

Panel Coker

The Falex Panel Coking Test Apparatus provides an economical method for the evaluation of coking tendencies of lubricants under a wide range of test parameters and test materials. The unit is equipped with three programmable temperature controllers (for regulation of the test panel, test oil in the sump, and air flow), a variable drive motor […]